This is a review and setup guide for the new BeerotorF3 (BRF3) all-in-one (AIO) flight controller from Rctimer.

Overview

Update Aug, 2016: The new Omnibus flight controller is out. If you're looking for a high performance flight controller with a directly integrated OSD, this is the board for you.

You probably know why having an OSD that displays current consumption is so important, but I'll reiterate it anyway. A current sensor measures the exact amount of battery that has been used and the OSD displays this information as text overlaid on your video feed along with all the other available sensor data like RSSI, Voltage, mA currently in use, total mAh consumed, flight mode, an artificial horizon and GPS coordinates. This way you know exactly when you're going to run out of battery.

The BRF3 adds a barometer which will give you altitude information as you fly.

Before the BRF3, to get all my stats to display on an OSD, I had to build something like this, with a mess of different wires and 4 discrete components:

With the BeerotorF3, those 4 components (current sensor, Blackbox, PDB and OSD) look like this:

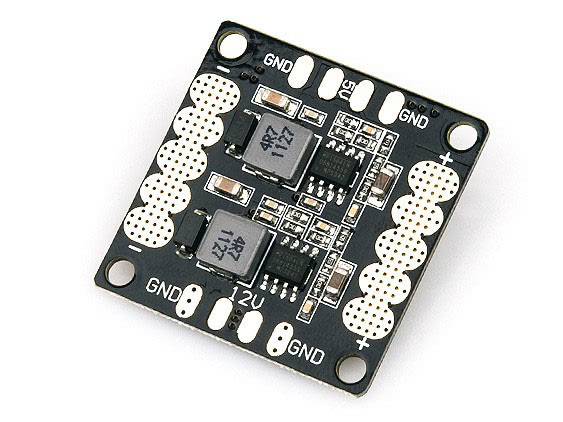

The bottom board shown in the photo above is the companion Beerotor PDB (BRPDB), which carries a shunt resistor current sensor and 28v (6s) compatible MP1593DN voltage regulator.

BRF3 and PDB weigh only 13g, compared to 22g for 3 discrete components: PDB, NAZE32 and MinimOSD. Plus you would need to get a current sensor if you went with the discrete setup.

Stacked together, the boards are 16mm tall. With two sets of 5mm standoffs, which allows for a little bit more comfortable mounting, it's 22mm tall.

Pinouts

Top:

Bottom:

The full manual is here: http://www.rctimer.com/download/BeeRotorF3Manual.pdf

Why choose the BRF3?

You're probably thinking, why should I buy a BeerotorF3 when there are so many flight controllers on the market.

The advantages over a Naze32, SpracingF3 or Oze32 are numerous but the decision when choosing any flight controller boils down to three things:

Flight Performance

Update July, 2016: It has come to my attention that there are a few performance issues with this board. First, the Gyro (IMU) interrupt is not connected, which means that the flight controller needs to do more work to process the sensor data, slowing down the processor overall. Second, the Gyro is connected via the slower I2C interface instead of SPI. Finally, the BeeRotorF3, like the SPRacingF3, use a USB/UART adapter, which is very slow when transfering blackbox log data out of the flight controller. The new Omnibus flight controller also uses an F3 processor, but fixes the issues with the BeeRotorF3. The Omnibus also has an OSD directly integrated in the flight controller, an improved MPU6000 gyro, uses VCP instead of a USB/UART adapter (the VCP is much faster) and has an SDcard blackbox logger.

Without flight performance, none of the other things matter, so let's look at that first. If you're already convinced that F3 processors are better than F1, just skip to features.

If you're not already, you should be flying BetaFlight. Unlike the name sounds, BetaFlight is actually very stable.

The un-tuned flight performance of BetaFlight is amazing. It also implements many features that may or may not make it into CleanFlight such as filters that will allow 2khz and possibly 8khz loop times, AirMode and a task scheduler.

We'll use that final feature, the task scheduler, to compare performance between a Naze32 (running an STM32F1) and the BRF3 which runs a STM32F3.

The F3 and the F1 run at the same clock speed, 72MHz, but the F3 has a floating point co-processor which allows it to do floating point math off-cpu. This means that it can run the LuxFloat PID controller, which is much more accurate and feels more "locked in" than the normal "Rewrite" PID controller.

Using the status CLI command in BetaFlight, we can ask the task scheduler how busy the CPU is and it will tell us System load. 1 is equal to 100%, so if we're above 1.0, the copter will not arm. It just can't do everything we've asked it to do within the looptime specified.

Here's what my NAZE32 says when I try to run LuxFloat, even after disabling the magnetometer:

System Uptime: 20 seconds, Voltage: 0 * 0.1V (1S battery - NOT PRESENT), System load: 4.08

CPU Clock=72MHz, GYRO=MPU6050, ACC=MPU6050.n, BARO=MS5611

Cycle Time: 993, I2C Errors: 0, config size: 2020

Notice the load of 4.08, that's means the system load is 408%, which just not going to work...

Here's what the BRF3 says:

System Uptime: 816 seconds, Voltage: 0 * 0.1V (1S battery - NOT PRESENT), System load: 0.07

CPU Clock=72MHz, GYRO=MPU6050, ACC=MPU6050.n, BARO=BMP085

Cycle Time: 1012, I2C Errors: 2, config size: 2060

Wow. 7% load.

I did some further testing, taking the average free processing time for both the F1 and F3 processors. These were taken with the following sensors enabled: GYRO:MPU6050, ACC:MPU6050, BARO:BMP085. There are no data points for 2khz on the F1, since it is not possible to run 2khz with these sensors enabled. The closer a value is to 100%, the better.

In terms of performance, as long as system load is under 90% or so, it really doesn't matter. Once it runs, less load doesn't make it faster. What it does mean though is that 93% of CPU time is available for other processing. With 93% CPU time left, we should have no problem running GPS, MSP, LEDs, etc.

That's what it really comes down to: free processor capacity. The F3 will allow you to run so many more features, like when the iNav fork is ready (it's still under development), adding GPS will allow autonomous flight, but you'll need a board with enough free processor capacity.

The other thing you'll want, to enable more features and sensors, are more UARTs. There are only 2 on the F1 processor and 3 on the F3 processor. These are considered "Hardware Serial" ports, which don't take extra processor time. The F3 processor is fast enough to support a few more "Software Serial" ports, which do take extra processor time and therefore are probably not usable on the F1 board. You'll never want to put a critical component, like a serial receiver on a software serial port. Same goes for GPS if you're using it to navigate. OSD might be OK on software serial, but it's already wired to a hardware UART on the AIO boards (like the OZE32), so the OZE32 won't support GPS navigation.

You'll notice from the Beerotor system status that we don't have a magnetometer on the board. Perhaps surprisingly, this is ideal.

Features

Like all F3 boards, we have 3 hardware UARTS.

On the BRF3 they're mapped as follows.

-

UART1- wired to the onboard OSD's ATMEGA328p -

UART2- GPS, next to the I2C pins -

UART3- Serial RX, wired into the Spektrum Satellite port, also next to RSSI on the SB port.

Magnetometer and GPS

As we can see from the status output in the performance section, you get an IMU and Barometer on the board, but no magnetometer (e.g. compass).

If you've faced issues with a noisy compass, you know it's always better to have a magnetometer you can move away from any magnetic-field-generating current loops (e.g. PDB and motor leads). Even a few inches can make a big difference.

The problem with having a built-in magnetometer goes back to how the I2C bus works. I2C is the protocol used by the magnetometer to talk to the flight controller. I2C expects every device on the bus (a bus is just a bunch of sensors all connected on the same set of wires) to have a unique ID. However, every device does not have a unique ID, the ID is tied to a particular type of sensor. For example, the HMC5883 magnetometer on the NAZE32 has a unique address, but if you attach another HMC5883 to the I2C bus, they both have the same address and neither will work.

For flight controllers that have an on-board compass, the traces to the can be cut. Then, plugging in an external magnetometer will work, but with the BRF3, you won't need to do this!

Just get a GPS with a magnetometer, like this NEO-M8N with a compass and plug it in here:

I2C ports are for the compass

UART2 is for the GPS. Be sure to enable GPS for UART2 in the configurator

MinimOSD

The really exciting part about this board is the on-board MinimOSD. A minim osd is basically two chips: the MAX7456 chip and ATMEGA328p, which you can see on the bottom of the board:

The MAX chip is in charge of drawing characters onto the video signal and the ATMEGA chip tells the MAX chip what characters to draw.

For this to work, the MAX chip needs the video signal to pass through it, in one pin and out another, so you'll need to wire the SD port in-line with your camera and video transmitter:

VIDEO_IN is the yellow line from the camera (video signal)

VIDEO_OUT goes to your video transmitter

Use the ground, if you have a lead from the camera and to the transmitter available, to minimize as much noise as possible.

Back to how the MinimOSD works: the ATMEGA chip decides what to tell the MAX chip to write. The way it does this is by asking the flight controller what is going on. It communicates with the BRF3 in this case, over UART1. It talks the same protocol as the configurator: multiwii serial protocol (MSP).

This is important because it means that on the BRF3 UART1 is wired to the ATMEGA's UART port. Therefore, to talk to the MinimOSD for upgrading and configuration, we need to make sure the BRF3's STM32F3 is turned off and the ATMEGA is turned on. To power just the ATMEGA, connect the provided FTDI cable to your handy UART/USB adapter and use the Scarab OSD configuration tool to configure the MinimOSD.

The colors in the photo correspond to:

-

black- ground -

red- 5v -

orange- TX -

yellow- RX -

green- DTR (e.g. reset)

Remember that when connecting UARTs, one TX goes to the other RX, so in this case orange will go to RX on the UART/USB adapter.

Unlike the OZE32, there are no dip-switches, which is a great improvement.

When working with the on-board MinimOSD, remember:

-

UART1 must have MSP assigned in the configurator to communicate with your computer via USB and with the ATMEGA chip

-

The board is designed such that when a USB cable is plugged in, the ATMEGA chip will be turned off, so we can communicate with the BRF3's STM32 chip

-

The MinimOSD can only be configured or updated when the USB and battery are unplugged

-

Connect only the FTDI adapter cable to the

SEport to upgrade or configure the OSD

-

-

Powering the board via a battery or any 5v lead will turn both the ATMEGA and STM32 on. This is "Flight Mode." When both are powered, the OSD should show data from the flight controller on your display.

Also, there is an open pull request against CleanFlight that makes it possible to configure the MinimOSD by communicating through the STM32: https://github.com/cleanflight/cleanflight/pull/1620. When this feature is finished, we won't need to go through all this to configure the MinimOSD, we'll be able to do it all via the normal USB connection.

DataFlash

The BRF3 has 8MB of flash for blackbox logging. This is way more than the 2MB included on the CC3D and full NAZE32. Flash, by the way, is way faster than an SDCard-based OpenLog device, so you'll never miss a frame of data.

Run this in the configurator CLI to enable it:

feature BLACKBOX

set blackbox_device=SPIFLASH

save

Value

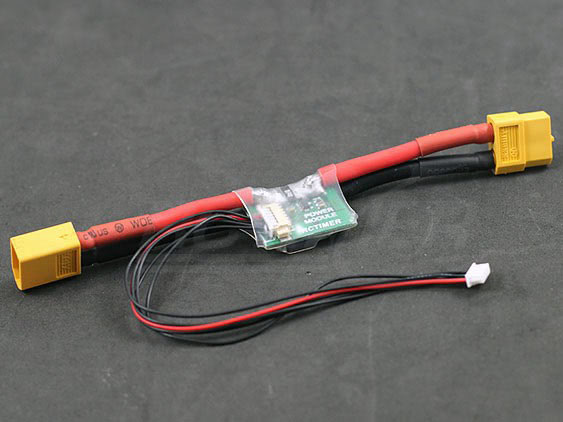

To get a comparable setup, in discrete components, we would need:

This totals up to $49.96. Plus, you're stuck trying to figure out where to put that giant MinimOSD and the power module with the current sensor. It's so much nicer having it all in one place, ready to go.

At $34.99 for the BRF3 and $5.99 for the BRPDB, the Beerotor setup is $40.98. Not only is it smaller and lighter than buying discrete components, it's cheaper too!

Hardware

The build quality and hardware layout on this board is great.

The USB is on the side, so no need to mess with the board orientation in the configurator.

The baro is on the top of the board, so be sure to cover that with some open cell foam, or mount it upside-down and put a piece of open cell foam between the frame and the baro. Wind passing over the top of the baro can significantly decrease it's accuracy.

If you look closely at the inside of the mounting holes on the BRF3, you'll note these are not coated with conductive material. This is great as it means the board can be safely mounted with metal screws or standoffs on a carbon fiber frame.

Motor outputs

I'm a big fan of the small DF (also called SH) connectors. These are the long white plugs. They save space and are much easier to work with than the 2.54mm JST servo-style pins. Plus it makes stack-mounting multiple 35x35mm boards possible. The connectors on the BRF3 have been upgraded from SH1.0 to SH1.25, meaning the pins are ever so slightly larger and more robust, but the connector size is still tiny. Plus, this is the same pin spacing as the PixHawk, which means you can start re-using cables between some projects!

They even put a boot-button on the board! This is awesome. No more getting out the tweezers every time I want to short the boot pins to upgrade BetaFlight!

The motor output pins are through-hole vias, ready for some male 2.54mm headers. Motor 1 is on the left, 8 is on the right.

If you want to use pin headers, grab some right angle 2.54mm pins, my board didn't come with any. I think it will save weight and space to just solder the ESC leads right onto the flight controller, so I'll skip the pin headers. At some point, I hope all the flight controllers standardize to SH1.25 connectors and ESCs ship either without signal wires or with signal wires that terminate in a single female connector that fits into a SH1.25 connector.

You'll also want to wire your ESC signal ground wires to the board.

Receiver

The Spektrum Satellite port is here:

S.Bus, SUMD:

Although I don't have an S.Bus RX to confirm this, it looks like an external inverter is not necessary. It should work fine plugged in directly to UART3. Make sure you take either 5v from the same port or 3.3v from the Spektrum port, depending on what voltage your receiver can handle.

The RSSI analog to digital converter (ADC) is on the SB port as well, along with PPM input.

Note that the UART3 RX pin is available on both port SA and port SB. Either can be used.

Flashing

For the complete flashing guide, see the Victory230 Flashing Guide.

Like all F3 chips, make sure you set the manual baud rate to 256000. I also set Full chip erase when switching to BetaFlight.

Download the latest version of BetaFlight from the github.com release page https://github.com/borisbstyle/betaflight/releases/. You want the file: betaflight_SPRACINGF3.hex

Click the Load local firmware button and pick the SPRF3 hex file.

Click Flash Firmware

If for some reason that doesn't work, flashing via bootloader mode is amazingly easy. Just unplug the BRF3, hold the boot button down while you power it on by plugging it into USB. Choose No reboot and hit flash.

Configuration

For the complete configuration guide, see the Victory230 Configuration Guide.

If you're using the BRPDB, after flashing you'll want to set these options. Paste them in the cli:

set vbat_scale = 210

set current_meter_scale = 380

save

This will calibrate the flight controller to the PDB's voltage and current sensor hardware.

Receiver

Serial RX

The Serial RX connection looks like this. I'm using SBUS. The white wire is the SBUS signal and the grey wire is the RSSI-ADC. We'll actually get RSSI on SBUS channel 9 with this DIY FrSky module, so they grey wire is actually not necessary with this receiver. You may or may not need the grey RSSI-ADC wire attached, depending on your RX.

Enable Serial RX for UART3 on the Ports tab then hit Save and Reboot

On the Configuration Tab set Receiver Mode to Serial RX and choose your Serial Receiver Provider, I'm using SBUS

To get RSSI on SBUS channel 9, set:

set rssi_channel = 9

set max_aux_channels = 5

If you're using OpenLRS or a DIY FrSky module, set sbus_inversion off

set sbus_inversion=OFF